What Happens If a Clutch Has No Free Play?

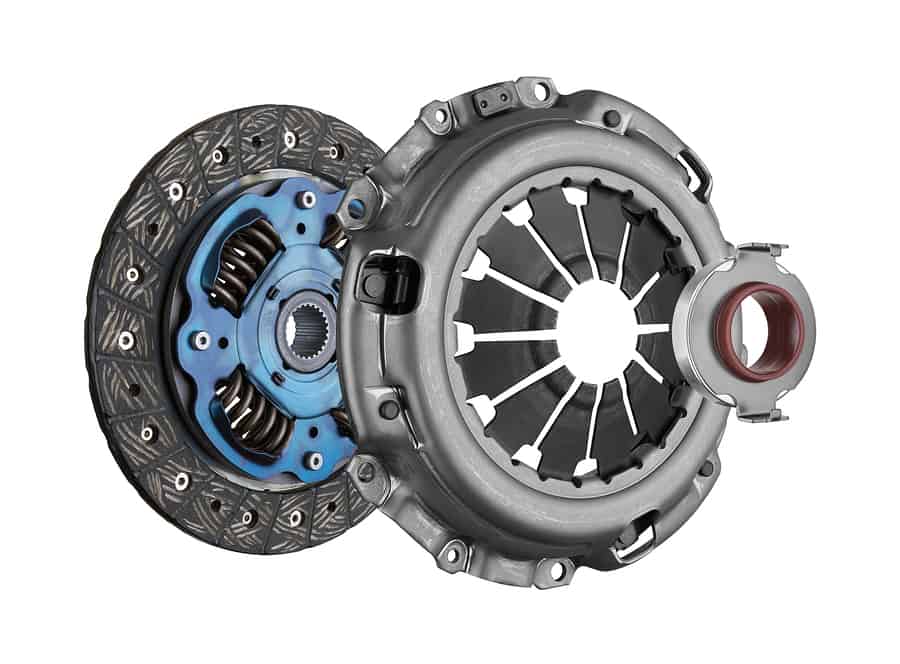

Occasionally, the clutch on your car may have no free play. This can be due to the disk or flywheel being worn or a pressure plate diaphragm spring has failed. What Happens If a Clutch Has No Free Play? There are several ways to fix the problem and the first step is to check the clutch pedal for signs of wear. You can also resurface the flywheel or replace the clutch disk.

Post Contents

What Happens If a Clutch Has No Free Play?

Traditionally, friction clutches were fitted with coil springs. However, they can be made more efficient by using a plate spring. This is especially useful if the free end areas of the tongues or extension arms are in a plane that is perpendicular to the axis of rotation.

The present invention provides a simple and cost-effective way to adjust the height of the individual fingers of a diaphragm spring. This can be done using a device comprising movable ram and self-centering bearings. The device can be configured to align the tongues of the plate spring radially inwards. It also has the ability to bring the radial inner tongue tips to the same axial height.

The present invention also provides the ability to achieve a partial heat setting in a particular area. This is achieved by radiating heat into an elastically deformable region. This can reduce the elastic tension of the finger, which reduces wear and tear. The area can also be cooled down after the adjustment. Also, check out the Clutch Charger Review.

The present invention also provides the ability for a plate spring to be thermally finished. This can be achieved by locating an area in the ring-shaped foundation body of the plate spring where it can be heated. This area can also be heated to a temperature that is sufficient to achieve partial hardening. This can reduce the tensions between the tongues.

The present invention also provides the ability of a plate spring to be fitted with a pressure member on its tongue tips. This can be achieved by positioning the ring-shaped foundation body in such a way that the area corresponding to the pressure member is heated to a temperature that is sufficient to produce a partial hardening.

The present invention also provides the ability of a device to align the relative paths of the fingers of a diaphragm and the plate spring radially inwards. This is accomplished using a device comprising a ring shaped foundation body, a pivot ring, and a pair of self-centering bearings. The pivot ring is sized to be able to move in a 2/1000 mm increment.

Adjust the clutch pedal

Depending on your vehicle, you may need to adjust the clutch pedal if the clutch has no free play. Improper free play can cause gears to clash when shifting, and can also wear out the release bearing. Excessive free play may also cause your car to creep forward when changing gears.

To adjust the clutch pedal, you will need to turn the linkage. You should be able to find the linkage’s threaded end at the bottom of the clutch fork, or under the pedal box. Turn it until you can feel a bit of resistance. You can then use pliers to grip the threaded end of the cable. Once the cable has been turned, you will need to tighten the nut on the linkage. This will allow you to make more travel, which will decrease free play.

You can also adjust the linkage by shortening the rod’s effective length. You can also add a shop rag to clean and lubricate the rod. Once the rod has been turned, you will be able to adjust the pedal height.

You should use the same method to adjust the pedal’s free play if the pedal has no free play. This method will only shorten the length of the push rod. If you have a stock disc, you may need to increase the pressure plate spring force to make your clutch pedal easier to slip.

The adjustment of the clutch pedal is also possible on hydraulic clutches. Unlike OEM clutches, the friction disc is thicker. As the pedal is depressed, the thicker disc bites sooner. The pedal should engage smoothly after a few depressions.

When adjusting the clutch pedal, you will need to use a ruler or tape measure. Set it alongside the clutch pedal, and make sure it is at least halfway down. You may need to use a block of wood to mark the pedal height. You will then need to press the pedal several times. Eventually, the pedal will stop at the height that you have measured.

After you have adjusted the pedal, you should also measure the distance between the adjuster nut and the inner edge of the clutch operating lever. This distance is known as clearance. This measurement must match your car’s service manual.

Resurface a worn flywheel

Generally, you should replace your flywheel if it is worn. The friction surface of the flywheel is what helps make the clutch work, so if it is worn, you will not be able to use the clutch.

If you experience a burning smell, it could be the flywheel, but if you hear a clunking noise from the clutch, you could be in need of a new flywheel. Clutch parts are known to be very high-wear components, so a new flywheel is probably not a bad idea. If you have an experienced mechanic, they will be able to do it for you. The cost of a new flywheel can range from $50 to $400.

Getting a new flywheel can save you a lot of money, so if you’re experiencing clutch problems, it may be time to get a new one. The cost of a new flywheel will vary based on your car and the type of flywheel.

Some common symptoms of a bad flywheel include a burning smell, gear slippage, and noises that make the car vibrate. These symptoms are pretty much the same for all manual transmission vehicles. However, there are some more specific symptoms that you should pay attention to, depending on the make and model of your car.

The flywheel may be warped, which will cause a rough take-up of the clutch. It may also have grooves or cracks that should be repaired. When you have a new clutch disk facing, you will need to resurface the flywheel to match the friction surface.

A good way to determine if you need a new flywheel is to take your car to a mechanic for a diagnosis. If a mechanic says that you need a new flywheel, then you will most likely need to replace it. However, if you have some knowledge about cars and are able to do some basic maintenance, you may be able to save some money and do the job yourself.

Resurfacing the flywheel is one of the most common clutch replacement jobs. The procedure is fairly straightforward. The flywheel is removed and then resurfaced, using fine sandpaper and a small rotary sanding disc.

Replace the clutch disk

Using the correct amount of free play is essential to the longevity of your clutch. A clutch that does not have sufficient free play can wear out the release bearing, the clutch fork return spring, and the clutch pedal pivot.

Some manufacturers suggest that you check your free play every 6,000 miles or so. This will give you a baseline. Once your free play is within the manufacturer’s range, your clutch will function properly. Occasionally, you may have to adjust your clutch pedal to get the free play that it needs. If you do, you should have a professional mechanic do it for you.

When your clutch disk starts to wear out, it may slip off the input shaft of your transmission. This is called clutch disc clutch slippage. It is a common problem. It can occur when the car is barely moving. It can be caused by a number of things, including a worn flywheel, a worn pressure plate, or a loose clutch pedal adjustment. It can also be caused by oil buildup on the disc.

The best way to check your clutch disk’s free play is to find the manufacturer’s specifications and compare them with your own measurements. Generally, you want the free play to be a couple of inches before your clutch engages. You can use a block of wood near the clutch pedal to mark its height. Press the clutch pedal a couple of times and then take measurements.

You can also find your clutch’s free play by looking at how much you depress the pedal. The more you depress the pedal, the more free play your clutch needs. If the free play is too low, the clutch will slip. If the free play is too high, the clutch may not engage properly.

When a clutch disk is worn, it may become glazed and lose grip. This can result in chatter and noise. You will want to replace the disk if you notice this.

Some manufacturers also recommend that you check the clutch pedal free play every ten thousand miles or so. This will ensure that your pedal will engage smoothly.

Next PagePrevious Page

Social Media Icons